- PID Auto-Tuning Most modern PID process controllers will support auto-tuning (also known as self-tuning ) of the PID settings. Typically the way this works will depend on which manufacturer’s product you are using, but commonly they use a rule based calculation in the same way that an experienced engineer tuning the device manually would.

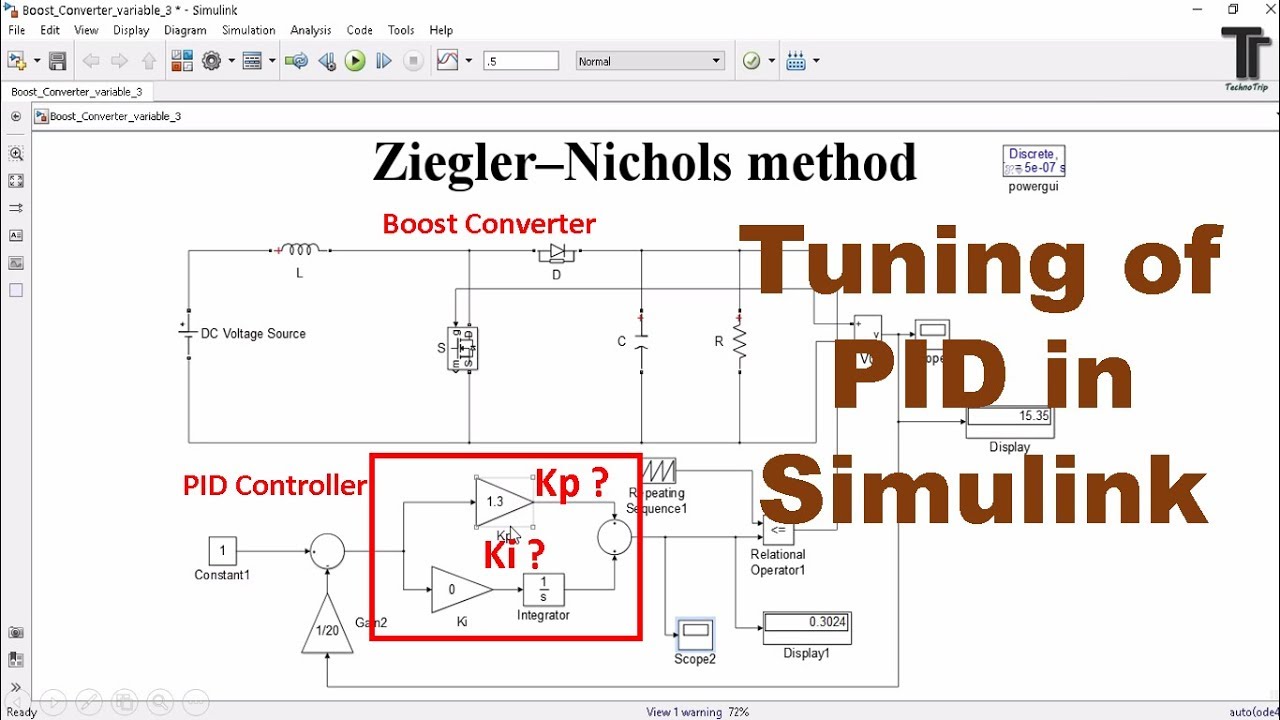

- B.PID parameters tuning The ultimate point can now be used to tune the parameters of the PID controller. The tuning results were compared to the ZN bode plot method using the MSE criteria. (11) The results presented in Figure 4 present a step responses for each of the four systems using both relay feedback parameters and bode plot ZN parameters.

- Most PID controllers sold today incorporate auto-tuning functions. Operating details vary between manufacturers, but all follow rules where the controller “learns” how the process responds to a disturbance or change in set point and calculates appropriate PID settings.

- PID tuning involves the entire process. The device used to switch the heater is not particularly relevant. Every system is different and will in general require individual parameter sets. Google 'PID tuning' for lots of tutorials.

This video shows you how to use PID instruction with Auto Tune User-Defined Function Blocks on Connected Components Workbench Software Release 10.0.

How PID Autotuning Works

To use PID autotuning, configure and deploy one of the PID autotuner blocks, Closed-Loop PID Autotuner or Open-Loop PID Autotuner.

Autotuning Process

The PID autotuner blocks work by performing a frequency-response estimation experiment. The blocks inject test signals into your plant and tune PID gains based on an estimated frequency response.

The following schematic diagram illustrates generally how a PID autotuner block fits into a control system.

Until the autotuning process begins, the autotuner block relays the control signal directly from u to the plant input at u+Δu. In that state, the module has no effect on the performance of your system.

When the autotuning process begins, the block injects a test signal at u out to collect plant input-output data and estimate frequency response in real time.

If you use the Open-Loop PID Autotuner block, the block opens the feedback loop between u and u+Δu for the duration of the estimation experiment. It injects into u+Δu a superposition of sinusoidal signals at frequencies [1/3, 1, 3, 10]ωc, where ωc is your specified target bandwidth for tuning. For nonintegrating plants, the block can also inject a step signal to estimate the plant DC gain. All test signals are injected on top of the nominal plant input, which is the value of the signal at u when the experiment begins.

If you use the Closed-Loop PID Autotuner block, the plant remains under control of the PID controller with its current gains during the experiment. Closed-loop tuning uses sinusoidal test signals at the frequencies [1/10,1/3, 1, 3, 10]ωc.

When the experiment ends, the block uses the estimated frequency response to compute PID gains. The tuning algorithm aims to balance performance and robustness while achieving the control bandwidth and phase margin that you specify. You can configure logic to transfer the tuned gains from the block to your PID controller, allowing you to validate closed-loop performance in real time.

Workflow for PID Autotuning

The following steps provide a general overview of the workflow for PID autotuning.

Incorporate a PID autotuner block into your system, as shown in the schematic diagram.

Configure the start/stop signal that controls when the tuning experiment begins and ends. You can use this signal to initiate the PID autotuning process at any time. When you stop the experiment, the block returns tuned PID gains.

Specify controller parameters such as controller type and the target bandwidth for tuning.

Farming simulator 2015 free full. download. Configure experiment parameters such as the amplitudes of the perturbations injected during the frequency-response experiment.

Start the autotuning process using the start/stop signal, and allow it to run long enough to complete the frequency-response estimation experiment.

Stop the autotuning process. How to play a wii. When the experiment stops, the autotuner computes and returns tuned PID gains.

Avast restore file from vault. Transfer the tuned gains from the block to your PID controller. You can then validate the performance of the tuned controller in Simulink® or in real time.

For detailed information on performing each of these steps, see:

See Also

Closed-Loop PID Autotuner | Open-Loop PID Autotuner

Related Topics

Going from a finished print to a great print takes a lot of calibration steps. Besides having the heatbed leveled correctly, and the extruder perfectly calibrated to melt just enough filament, the temperature of the hotend and the heatbed is just as important.

Today I am going to show you how to perform a PID Tuning to have constant and accurate temperatures during your prints.

What is PID Tuning?

Before starting with the guide on how to do a PID tuning, we fist need to understand the concept. In just a few words, PID is an algorithm that makes sure the heaters for both hotend and heatbed supply just enough heat in order to have the difference between the highest and lowest temperature as small as possible.

If you are interested in learning more about what is PID, you can check this Wikipedia article where a PID controller is described

Prerequisites for 3D Printer PID Calibration

In order to perform a successful 3D printer PID tuning, you need to have the 3D printer connected to your computer via USB.

Next, you need to access the terminal for your printer firmware. Today I will use Pronterface but anything will do, as long as you are able to send G-Code commands to the printer.

Hotend PID Tuning

Now that we have the 3D Printer connected to the computer, we can start the Hotend PID Calibration.

- Get the current PID settings using the

M503command. Your printer will return the current PID settings. - Run the

M106 S255command in order to set your cooling fan to 100% - Run the

M303 E0 S215 C8command and wait for the process to finish.

The message “PID Autotune start” will appear in the terminal. Your hotend will start to gradually heat and get new readings.

While the hotend PID Calibration is underway, let’s understand the command we ran.

M303 – This command initiates a process of heating and cooling to determine the proper PID values for the specified hotend or the heated bed.E0 – This argument selects the extruder we want to calibrate. I have only one extruder, so I will set it to 0.S215 – This argument sets the temperature for the extruder PID Calibration to 215C.C8 – This argument sets the number of cycles we want to run. I selected 8 because it’s the recommended value in Marlin firmware, but any value from 3 to 10 is great.

When the message “PID Autotune Finished” is displayed in the terminal window, the hotend PID Tuning is complete.

You will also see new Kp, Ki and Kd constants that need to be saved so let’s do that now. The previous values were so we need to adapt the command with the new values and save them.

- Run the

M301 P24.36 I1.39 D106.76command to add the new values - Run

M500to save the values. - Run

M503to check your current values. These should be the same as the values we just saved.

Heatbed PID Tuning

If you managed to perform the hotend calibration, then the heatbed PID Calibration will be much easier.

Arduino Pid Autotune

- Get the current PID settings using the

M503command. Your printer will return the current PID settings for the heatbed. - Run the

M303 E-1 S60 C8command and wait for the process to finish.

Arduino Pid Motor Speed Control

The message “PID Autotune start” will appear in the terminal. Your heatbed will start to gradually heat and get new readings. While the heatbed PID calibration is underway, let’s understand the command we ran.

M303 – This command initiates a process of heating and cooling to determine the proper PID values for the specified hotend or the heated bed.E-1 – This argument selects the heatbed we want to calibrate. I have only one heatbed, so I will set it to 1.S60 – This argument sets the temperature for the heatbed PID Calibration to 60C.C8 – This argument sets the number of cycles we want to run. I selected 8 because it’s the recommended value in Marlin firmware, but any value from 3 to 10 is great.

When the message “PID Autotune Finished” is displayed in the terminal window, the hotend PID Tuning is complete.

Pid Auto Tuning

You will also see new Kp, Ki and Kd constants that need to be saved so let’s do that now. The previous values were so we need to adapt the command with the new values and save them.

- Run the

M304 P824.78 I154.89 D1097.99command to add the new values - Run

M500to save the values. - Run

M503to check your current values. These should be the same as the values we just saved.

Pid Tuning Pdf

More information about PID Tuning can be found on the RepRap wiki